Threetom Modular Synthesizers

Tom Verschooten (male) is a multi-disciplinary engineer combining the fields of Electronics, Photonics, and Mechanical engineering. Tom received his Master’s degree in Industrial Sciences (Electronics) from the De Nayer Institute (Sint-Katelijne-Waver, Belgium) in 2009, and in 2011 he received his Master’s degree in Engineering Sciences (Photonics) from the Vrije Universiteit Brussel (Brussels, Belgium). With his theses “Credit Card Size Cochlear Implant Simulator” and “Feasibility study of Second Harmonic Generation of incoherent laser light” he was a laureate of the Barco and IE-net awards respectively. In 2011, Tom joined the Brussels Photonics Team (B-PHOT) of the Vrije Universiteit Brussel as a researcher in the domain of Biophotonics, contributing to the state-of-the-art of optical lab-on-a-chip systems and the online monitoring of lubricant oils. In 2015, Tom joins Imec, a leading international research & development and innovation hub, active in the fields of nanoelectronics and digital technologies. As a Test Engineer, he infuses the Imagers group with expertise on illumination systems and optomechanical assemblies. In 2016, Tom joins the Leuven based startup Bringme as an R&D lead engineer, developing state-of-the-art low-cost optical sensors for the company’s innovative parcel machine. After this exciting excursion, Tom returns to Imec in 2018. In his current role of R&D engineer, Tom is involved in the hardware aspects of testing Imec’s state-of-the-art imagers, of which some examples include building demonstrational setups, 3D printing camera bodies, design, and manufacturing of electronics for testing, and implementing laser and LED illumination systems.

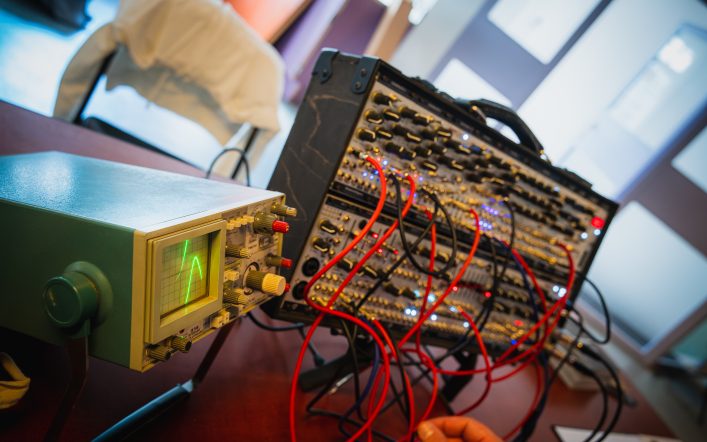

I initially got interested in music somewhere around 2007, after an impulse buy of a crappy electric guitar and amp. Since then my path as a musician has been a slowly meandering experience, learning the guitar from YouTube videos, taking lessons, switching to bass guitar, switching to piano, then back to bass guitar and then on to fretless bass and double bass (in which I eventually ended up getting a modest certificate). Around the time I got interested in playing the piano, I decided to get a more formal music education at the Conservatory of Mechelen (my home city). It’s here that I met one of my best friends Lode, who got me interested in synthesizers. My learning experience with synthesizers has been similarly meandering, dabbling with Ableton Live and hardware synths such as the Moog Little Phatty and Sequential Prophet Rev 2. Although I loved hardware synths, I always found it a bit frustrating that they are always limited to their internal routing architecture. Eventually, this got me into semi-modular synths like the Dreadbox Erebus and Make Noise 0-coast. Of course, these were just a gateway drug for getting into full-on eurorack modular synthesizers. I soon learned that modules are expensive and so I started building DIY kits to save some money (I had all the right tools for this lying around anyway due to my professional background). Since then I’ve learned about myself that I’m way more into building systems and modules rather than playing them.

The Threetom Story

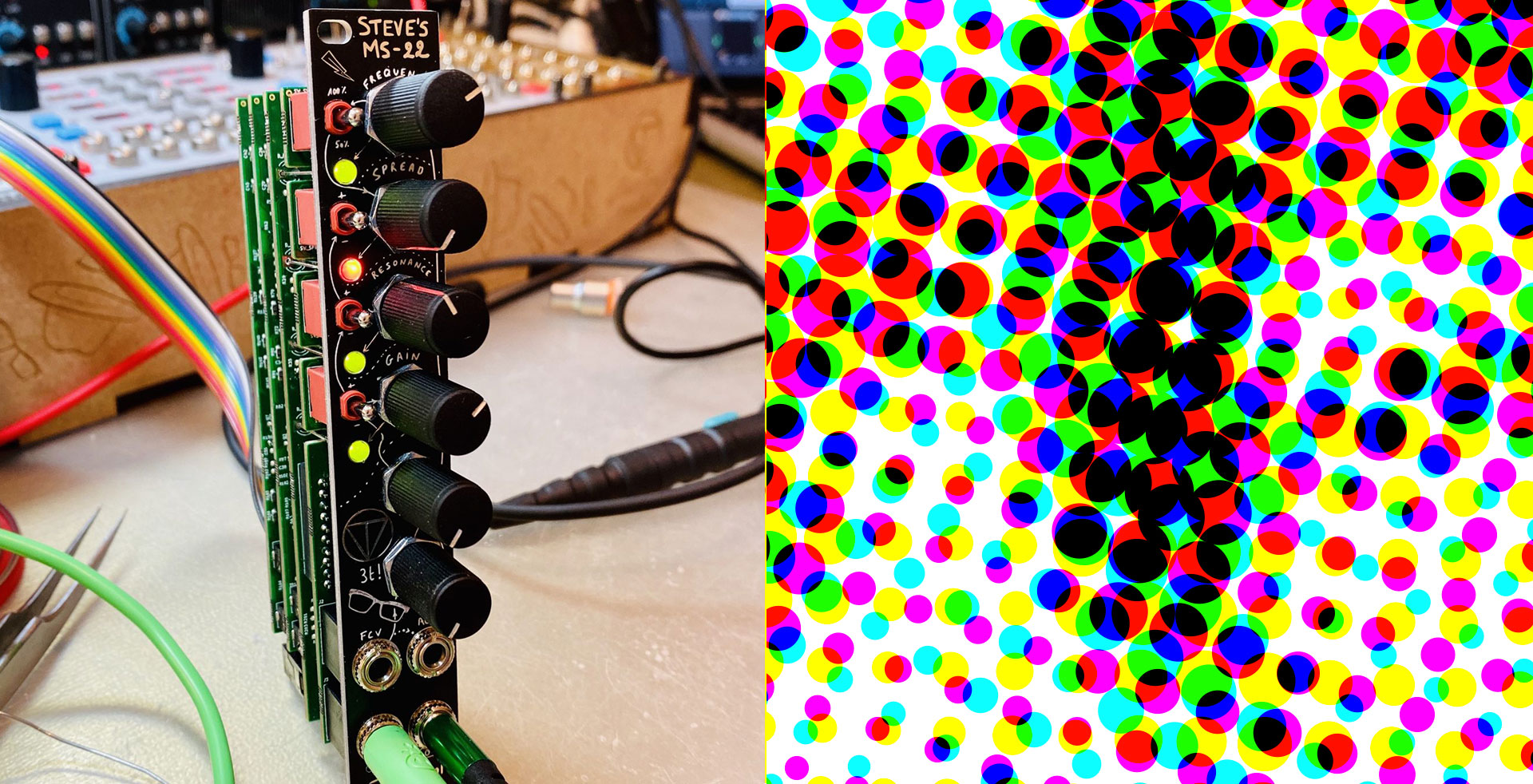

Somewhere in late 2018, I got to know tech journalist Steve O’Hear on Facebook. Back then, Steve was looking for someone to build him a DIY kit for a classic VCF clone. During our talks, he told me that in an ideal world he would have the same filter in a much smaller format. I thought that sounded like an interesting technical challenge, and so the ThreeTom story began. I then also decided to add some innovative features of my own, not only making the module much more interesting but even more challenging to design and build! I also decided that I’d like to commercialize these modules as I’d been looking for a passion project to turn into a first experience as an entrepreneur. I aim to be a small boutique shop that offers analog-only eurorack modules with unique selling points and good customer service.

Philosophy

I run my business based on the philosophy that ThreeTom is my “hobby that got out of hand” and I fully intend to keep it that way. Because of this, I consciously run ThreeTom in parallel with my full-time engineering job. There are two reasons for doing so: First of all, I find that people and projects at my fulltime job offer a lot of teachings and inspiration that are useful for ThreeTom. Vice versa, some of the things I learn whilst running ThreeTom tend to turn out useful for my full-time job. Secondly, if I were to run ThreeTom fulltime, I would “have” to be creative in coming up with new designs every few months to sustain a living. I’m sure this would burn out my creativity in the long run. Running ThreeTom as a side-venture gives me more creative freedom and results in less time pressure. Running a business on the side does have the drawback that the amount of time I can spend on it weekly is limited. I deal with this time limitation by making sure I have efficient processes and by taking sufficient time to meditate on new products.

Another practical consequence of my business philosophy is that I always work with limited batches. I will order a finite number of PCBs with preassembled SMD components per batch. As orders come in, I do the final assembly on a per-order basis (or turn them into DIY kits). This means that when you buy a module from me, I lovingly assemble, calibrate, and test that module specially for you as I’m not selling you a finished product lying on my shelf somewhere. I make it a point to personalize all products with a personal message in the box and adding your first name to the serial number on the back of a module. Of course, it will take a few weeks to build a module for you, but for quality products, I feel this is okay. I’m aware that my views regarding this are not in line with the current zeitgeist in which 1-day shipping has become something of a norm. I strongly feel that the anticipation of waiting for something custom built adds a deeper sense of appreciation for the product you end up receiving (“Hunger is the best sauce”). It kind of forces you to take your time to reflect on what’s coming, something we tend to do less and less in these ever hastier times. As a final note, I’d like to remark that quality products that are lovingly built will always be more expensive than mass-produced products. Although I try to keep my prices reasonable, I will never try to compete on cost. I aim to be competitive by focussing on quality, functionality, and service.

Website

Facebook